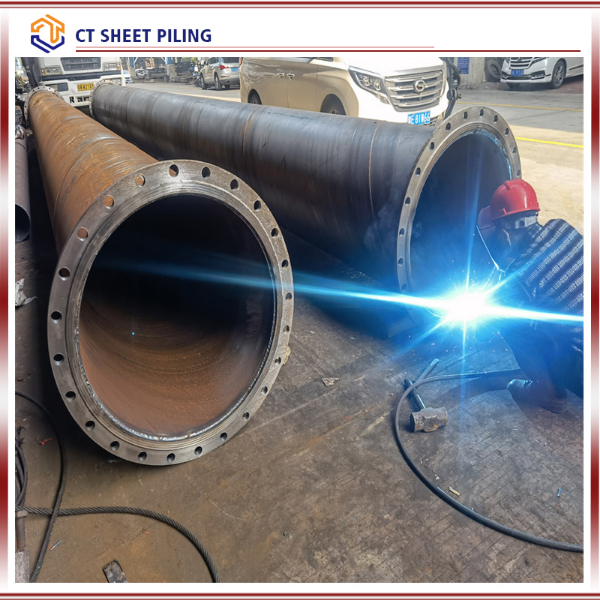

Tubular Piles Photos

Tubular Piles

Steel pipe piles are composed of steel pipes, tongued and grooved joints, and tongued and grooved pins. The left end of the pipe wall with a diameter of steel pipes is vertically connected to the tongued and grooved joint, and the cross-section of the tongued and grooved joint is a square shape with an opening on one side. There are reinforcing bars on the side of the tongued and grooved joint. The right end of the pipe wall with a diameter of steel pipes is vertically connected to the tongued and grooved joint, and the groove section of the tongued and grooved joint is an I-shaped joint.

The utility model overlaps the steel pipe piles in an arc or circular shape when used in cofferdams. It can play a role in enclosing water, soil, and sand. The utility model has the advantages of novel design, simple structure, convenient use, easy overlap, and good sealing performance. This includes cross-sectional contours that are non circular, of equal wall thickness, of varying wall thickness, of varying diameter and wall thickness along the length direction, and of symmetrical and asymmetric cross-sections. Such as square, rectangular, conical, trapezoidal, spiral tubes, etc.

Advantages of steel pipe piles:

1. Light weight, good rigidity, convenient loading, unloading, transportation, and stacking, and not easily damaged.

2. High bearing capacity. Steel has high strength, can effectively drive into hard soil layers, and the pile body is not easily damaged, and can achieve a large single pile bearing capacity.

3. The pile length is easy to adjust. Steel pipe piles can be adjusted in length by lengthening or cutting as needed.

4. Low soil discharge and minimal impact on adjacent buildings (structures).

5. The joint connection is simple. Electric welding can be used, which is easy to operate, high in strength, and relatively safe to use.

6. Reliable engineering quality and fast construction speed.

Tubular Pile Classifications

Pipe piles are produced from different steel grade for wide applications, for example, foundation pipes, king pile, monopile, bearing pile, pipe pile wall, slope stabilization, pipelines, deep foundation, and struts etc. Depending on the technology, tubular pipe can be classified as:

Spiral Submerged arc Welding pipe pile (SSAW steel pipe)

Spiral steel pipe pile is most frequently used with sheet piles to form tubular combined wall because SSAW pipes can be easily produced in very long length without extra welding and in very big diameters. Spiral submerged arc welding pipes are the ideal options for pipe pile wall,steel pipe piles, with steel interlock for clutch to connect two adjacent pipe piles. Spiral welded tubular pipes are produced from steel coils, welded both internally and externally. The width of steel coils used for steel pipe sheet piles can be varied, but in API standard, the material width should be from 80% of the OD to 300% of OD) Pipe shoes are normally welded to piling pipe due to driving considerations. Weld bead can be applied inside. In lots of cases, spiral piling piles are painted for pipe pile walls.

Longitudinally Submerged arc Welding pipe pile (LSAW steel pipe)

LSAW pipe piles are produced from steel plates, so the single steel pipe pile length can be maximum 16m without extra splicing. While Long welded pipes can be very thick, up to 100mm.Almost all pile shoes are longitudinal pipes. Longitudinal pipes can form with heavy pipe pile wall, with clutches, shear rings, and other fabricated components. These steel pipes are typically used in pipelines for liquid or gas or oil and petroleum casings. LSAW pipe pile can also be used as king piles and steel pipe piling.

Seamless pipe

Seamless pipes are produced by drawing a solid billet over a piercing rod, then the hollow pipe formed. Seamless pipes can withstand more pressure than any other steel pipes. When seamless pipes are used for steel pipe sheet pile, the project must have very strict quality controls. Seamless pipe piles are limited in OD and thickness, compared with Spiral welded pipes and Long welded pipes. Wide range of API steel grades and manufacturing standards are available here. Typical applications for seamless steel pipes are oil and gas line pipes, deep foundations,OCTG pipe, drilling casings and pipelines for pas or petroleum

Electric Resistance Welded Pipe (ERW pipe)

ERW pipes are cold formed from steel strip through the rolled. The OD of ERW steel pipes are normally within 600mm and wall thickness of ERW pipe piles are maximum 16mm.ERW piling pipes is a fast and cost effective solutions for steel pipe sheet pile. Electric resistance welded pipes are also typically used as dock piling, marinas, tunnels, columns and struts etc.